From Bioblast

|

High signal at zero oxygen |

MitoPedia O2k and high-resolution respirometry:

O2k-Open Support

Description

A high signal at zero oxygen may be observed during zero calibration (R0). First, check the quality of the dithionite solution. The following instructions show how to distinguish between a defective sensor head and an electrical leak current.

Reference: Zero calibration, OroboPOS-Connector

Leak current test

O2k-series J and XB

- Unplug the SmartPOS from the O2k-main unit.

- Remove the membrane from the SmartPOS and wash the cathode and anode with distilled water.

- Switch on the O2k and start DatLab.

- Record the signal for 10 min.

- Connect the SmartPOS to the O2k-main unit. Set an event in DatLab called "SmartPOS".

- Record the signal for 10 min.

- The leak current of each individual component should be stable and below 0.001 µA (DatLab 8). If the SmartPOS is giving a high leak current a sensor service frequently solves the problem. If you have any uncertainties, please forward the file to the technical support.

O2k-series D-I and XA

- Unplug the POS-Connector from the O2k-main unit and unscrew the OroboPOS from the POS-Connector. Screw the POS to the blue part of the perspex housing.

- Remove the membrane from the POS and wash the cathode and anode with distilled water.

- Switch on the O2k and start DatLab.

- Record the signal for 10 min.

- Connect the POS-Connector to the O2k-main unit without the POS. Set an event in DatLab called "POS-Connector".

- Record the signal for 10 min.

- Screw the POS to the POS-Connector. Set an event in DatLab called "POS".

- Record the signal for 10 min.

- The leak current of each individual component should be stable and below 0.001 µA (DatLab 8) or V (DatLab 7 and previous versions). Depending which component is giving a high leak current, a sensor service, followed by cleaning the electrical connections and drying the OroboPOS (without membrane) or the POS-Connector in an oven at up to 60 °C for 1-2 h frequently solves the problem. If you have any uncertainties, please forward the file to the technical support.

O2k-series A-C

- Plugging or unplugging of the POS-Connector while the main unit is switched on could damage the POS-Connector of O2k-series A-C. Therefore, the following should be started with the O2k switched off.

- Unplug the POS-Connector from the O2k-main unit and unscrew the OroboPOS from the POS-Connector. Screw the POS to the blue part of the perspex housing.

- Remove the membrane from the POS and wash the cathode and anode with distilled water.

- Plug the POS-Connector to the main unit.

- Switch on the O2k and start DatLab.

- Record the signal for 10 min.

- Screw the POS to the POS-Connector. Set an event in DatLab called "POS".

- Record the signal for 10 min.

- The leak current of each individual component should be stable and below 0.001 V (DatLab 7 and previous versions). Depending which component is giving a high leak current, a sensor service, followed by cleaning the electrical connections and drying the OroboPOS (without membrane) or the POS-Connector in an oven at up to 60 °C for 1-2 h frequently solves the problem. If you have any uncertainties, please forward the file to the technical support.

References

Example

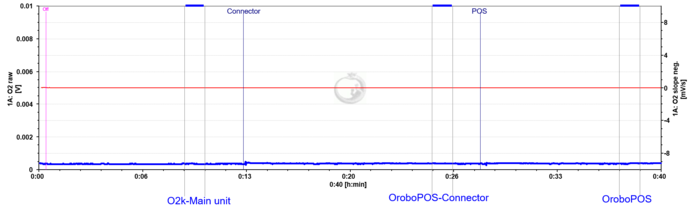

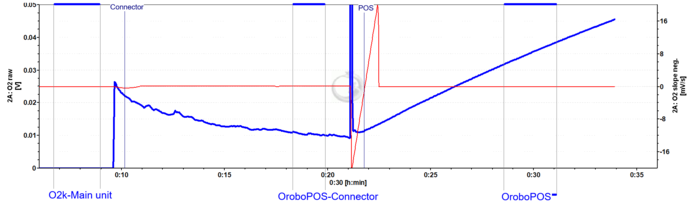

- First, the OroboPOS-Connector and the POS were disassembled and disconnected from the main unit. Second, the OroboPOS-Connector was connected to the O2k-Main unit without the OroboPOS. Third, the OroboPOS was connected to the OroboPOS-Connector without membranes. After each step, the O2 raw signal [V] was recorded for 10 min. The marks were set to the O2 raw signal [V] to evaluate the leak current.

- Figure 1. Leak current test. Upper panel: Leak current is in the range of ±0.00099 V. Lower panel: Leak current is higher than 0.00099 V when the OroboPOS-Connector is connected to the O2k-Main unit and when the OroboPOS is connected to the OroboPOS-Connector, indicating a potential electrical problem of both, the OroboPOS-Connector, and the OroboPOS.

Keywords

- Bioblast links: Oxygen signal - >>>>>>> - Click on [Expand] or [Collapse] - >>>>>>>

- Specific

- O2k-Procedures

- MiPNet O2k-Procedures

- General

- » Oxygen, dioxygen, O2

- » Oxygen calibration - DatLab

- » Oxygen solubility

- » Oxygen solubility factor

- » Oxygen pressure

- » Concentration

- » Activity

- » Pressure - Pascal

- » Barometric pressure

- » High-resolution respirometry

- » OroboPOS

- » Polarographic oxygen sensor

- » MitoFit Quality Control System

- » Sensitivity

- General

- Other keyword lists

MitoPedia O2k and high-resolution respirometry: O2k hardware, O2k-Open Support, O2k-Respirometry